Payment:

T/T,L/CProduct Origin:

Hefei,ChinaShipping Port:

Shanghai / NingboLead Time:

Within 7-20 daysProduct Name:

Glass sorterWarranty:

2 yearsMachine Function:

Color/material/shape/size sortingCertificate:

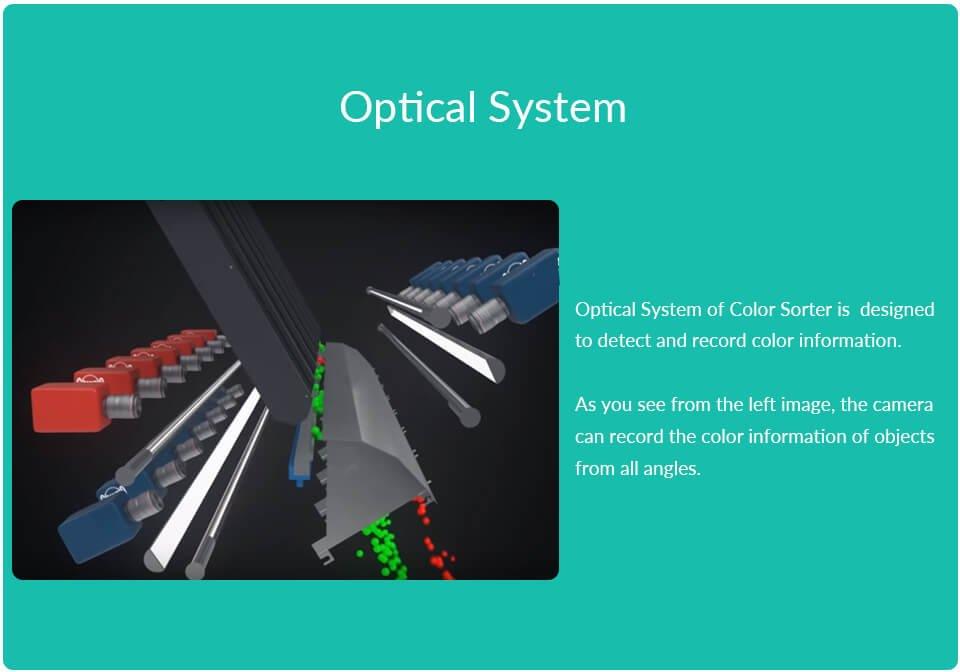

CEA glass color sorter is a sophisticated device leveraging photoelectric detection technology to automatically discern and segregate heterochromatic particles within granular materials based on their differing optical properties. Here's how it operates: the materials are conveyed to the exit end via belt transmission. At the exit end, a high-speed industrial camera capture card is employed. This industrial camera captures images of the materials, which are then relayed to the separation execution system. Subsequently, the system sorts the materials based on color disparities.

Glass Sorter Advantages and Factory Strengths

Our newest model glass color sorter : Firstly, it substantially enhances the efficiency and precision of glass sorting processes. Additionally, it mitigates labor costs and reduces associated risks. Opting for a glass color sorter represents a judicious and environmentally conscious choice for glass recycling endeavors.

Introducing our cutting-edge belt glass color sorter, a versatile solution designed to efficiently sort a wide array of broken glass types, including wine bottle glass,slag glass, flat glass and more. What sets this equipment apart is its innovative drum design, which facilitates sorting in both dry and wet conditions, offering unparalleled flexibility.

|

Model |

MKBCS640B |

MKBCS1280B |

MKBCS1600B |

|

Output(t/h) |

1.2-6 |

2.5-12 |

3.2-15 |

|

Carryover (bad: good) |

≥15:1 |

≥15:1 |

≥15:1 |

|

Accuracy (%) |

≥99 |

≥99 |

≥99 |

|

Voltage (V/Hz) |

220V/50HZ |

220V/50HZ |

220V/50HZ |

|

Power (Kw) |

1.0-1.3 |

1.6-2.6 |

2.0-3.3 |

|

Air pressure (Mpa) |

0.6-1.0 |

0.6-1.0 |

0.6-1.0 |

|

Consumption (L/min) |

<1024 |

<2048 |

<2560 |

|

Weight (Kg) |

1000 |

1360 |

1900 |

|

Dimensions (mm) |

3108*993*1680 |

3108*1986*1680 |

3108*2306*1680 |

Equipped with advanced technology, our belt glass color sorter boasts high sorting accuracy, ensuring precise separation of materials. It excels in effectively removing impurities such as variegated glass, ceramics, stones, metals, and plastics from the cullet material. By doing so, it significantly enhances the purity of the cullet, paving the way for seamless recycling of broken glass.

Whether it's in industrial settings or recycling facilities, our belt glass color sorter stands as a reliable solution, streamlining processes and contributing to sustainable practices. With its ability to deliver consistent results and optimize material purity, it plays a pivotal role in achieving efficient broken glass recycling.

Raw material -Before sorting

After sorting -Accepted glass

After sorting-Rejected glass

Raw material -Before sorting

After sorting -Accepted glass

From optical sorting to color vision sorting,and then to multidimensional fusion sorting. From computational intelligence to perceptual intelligence, and then to the iteration of cognitive intelligence, every technological revolution of HT is changing the world we are familiar with.

HT has grown for more than 20 years, and has gone deep into the processing industries such as beans, seeds,nuts, wheat and grains, focusing on advanced technical research on material sorting. HT' S new series of deep learning equipment brings multiple value experiences to customers for multi scenario applications.

Packaging & Shipping

Machines to be carefully packaged to endure transportation under harsh conditions. Handling instructions are designed to protect the machine in the critical moments during transportation, unloading and installation.

Delivery Time: 10- 20 Days after order confirmed.

Payment Terms: TT, Letter of Credit.

Commissioning and Installation

1. On Site Installation and Training Service by our professional engineer ;

2. Study and Learn the Machine Operation in Our Factory.

3. Responsive in 24 hours: Telephone, Email, Video or On Site Solutions by our Technical Experts.

More information about color sorter

Separate Materials By Color

Color sorters are intensively effective in sorting materials of different colors. Rice, grains, millets, and cereals are examples you might need to sort based on colors.

Separate Materials By Sizes

It is prevalent to sort foods by size. In general, a color sorter can sort products by sizes of 0.1mm to 100mm.

Separate Materials By Shapes

Sorting by shape is very useful to classify food like tea leaves and seafood. You can set the parameters you want and let the machine do the work.

Separate Materials By Types

In some cases, you might need to sort materials like nuts, seeds, and beans by type. To classify them efficiently and pick only the healthy ones.

Customer Feedback Is The Driving Force Behind Our Progress:

Plywood Case Is Suitable For Sea/Road/Air Transport:

1. How to use the machine?

We will supply the Installation instructions and videos for guiding you how to set color sorter.

2. How long about the guarantee period?

Two years. And we supply lifelong software upgrade services for our customers.

3. Can you supply the air compressor, air tank and air filters?

Yes, we can provide above equipments, our standard offer includes color sorter machine with air compressor & air tank & air dryer & air filters.

4. Is oversea service available?

Yes, we will send engineer go abroad when you need it.

5.How to calculate Installation personnel cost?

On condition that customer requires to install, our company would like to send 1 engineer to guide for installation, then customer should to pay the cost, including transaction of engineer’s visa, transportation(air) for go abroad. and accommodation , local transportation and security when the engineer arrived.

6. If you have agent in our country?

We have agent in UK,New Zealand,Italy,Crotia,India, Guatemala,Finland,Malaysia,Bangladesh,Pakistan,Nigeria,Ukraine,Nicaragua etc. and we can provide after-sales service in your Country.

We have many installation cases and working videos.Please contact us freely if you need.