Quartz Sand Sorting / Mineral Sorting/AI Silica Sand Color Sorter

Payment:

T/T,L/CProduct Origin:

Hefei,ChinaShipping Port:

Shanghai / NingboLead Time:

Within 7-20 daysProduct Name:

Ore powder SortingWarranty:

2 yearsMachine Function:

Color sortingCertificate:

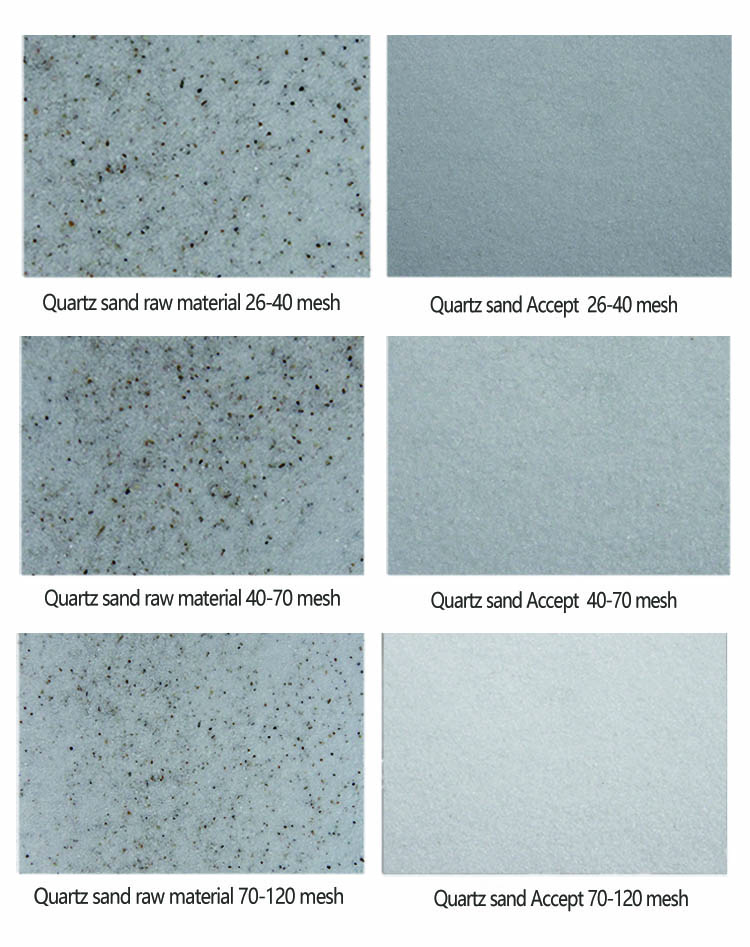

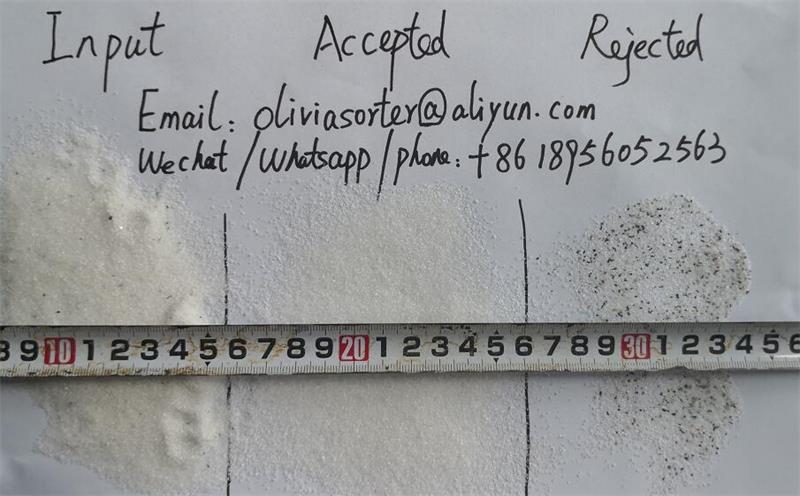

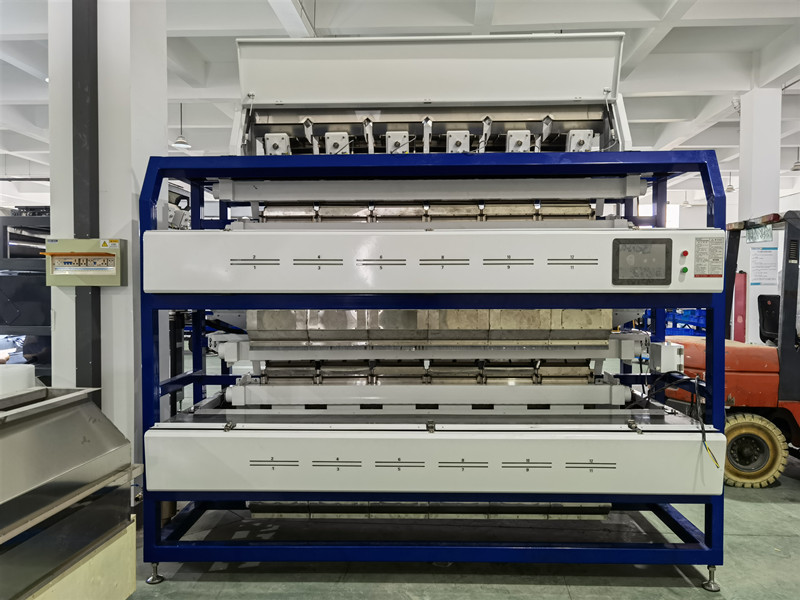

CEOur newest AI silica sand powder color sorter has best sorting accuracy.It can sort many different sizes quartz powder like 0.1-0.4mm (40-120mesh),0.1-1mm (16-120mesh ) ,sorting quartz powder by different colors .Mineral sorting can meet the specific surface of the special differences in mineral sorting, such as quartz, calcite, barite, wollastonite, talc, calcium carbonate, magnesia, silica slag, pebbles, gold ore, gangue, coal system Kaolinite, lead-zinc ore, copper ore and other minerals and some specific characteristics of the difference in materials.

Improve the added value of products and create greater benefits for enterprises. At present, our ore sorting machine is in many ores in China and the world.

We have special ore powder sorting equipment for powder size mineral,which is the most precise for powder.

The sorting of raw materials in rejects and pure product by means of optical sorting technology is an essential production step in reducing of production cost as well as for quality assurance of the final product.

Thereby optoelectronic sorting technology is the key to success! It comes to operation where mechanical approaches reach their limits. Tasks which were not solvable due to economic or technological aspects can today be solved with means of optoelectronic sorting technology.

Suitable range: potassium feldspar, gypsum, pebbles, talc, phosphate rock, silica, calcite, dolomite, andalusite, fluorite, vermiculite, mica, bentonite, kaolin, barite, feldspar, quartz etc.

Efficient ore color sorter changes traditional beneficiation model .

The emergence of ore optical sorting machine has broken the traditional mineral processing bottlenecks such as re-election, flotation, magnetic separation and pickling. The ore sorting method is more scientific and environmentally friendly! HIGHTTECH Ore Color Sorting Machine, sorting ore by color, sorting a variety of ore efficiently, and realizing the “three highs” requirement of “high output”, “high efficiency” and “high precision” for ore sorting!

HT fine particle quartz color sorting machine solves the big problem of fine particle color sorting that plagues the ore industry. The sorting range is 16-120 mesh(0.9-0.125mm). Such a particle that is difficult for us to identify with the naked eye, HT's fine particle ore optical sorting machine has been done .

Core Technology:

1. Newly designed LED light source,low power consumption and low heat .Solve the uneven illumination caused by the high temperature of the lamp.

2. Independent intellectual property design to solve the wear of ore particles on traditional chutes and impact of skipping on camera recognition

3. High-sensitivity CCD sensor with 5340 pixels and 12K scanning speed,with a unique scanning method,allowing the machine to select 120 mesh particles

4. The imported solenoid valve has a frequency of 1200Hz and high speed response.Low power ,low gas loss and long working life.It can be continuously energized for a long time to ensure stable production of large quantities of sorting

5. Using high-definition 4K full-color lens,large aperture,small distortion,high resolution.

6. Fully enclosed sorting box design,creating a dust-free working environment for the camera.Solved the problem of ash entering the camera caused by the poor sealing of the sorting box for a long time sorting.

|

Model |

Mesh |

Capacity |

Optional Carryover Rate(Rejected/Accepted) |

Air consumption |

Sorting Accuracy |

|

768A |

8-16 |

6-8 |

1:2 |

2600-3100 |

99.9% |

|

16-26 |

5-6 |

1:3 |

2500-3000 |

99.9% |

|

|

26-40 |

4-5 |

1:6 |

2200-2700 |

99.9% |

|

|

40-70 |

3-3.5 |

1:10 |

1500-2000 |

99.9% |

|

|

70-120 |

3-3.5 |

1:20 |

1500-2000 |

99.9% |

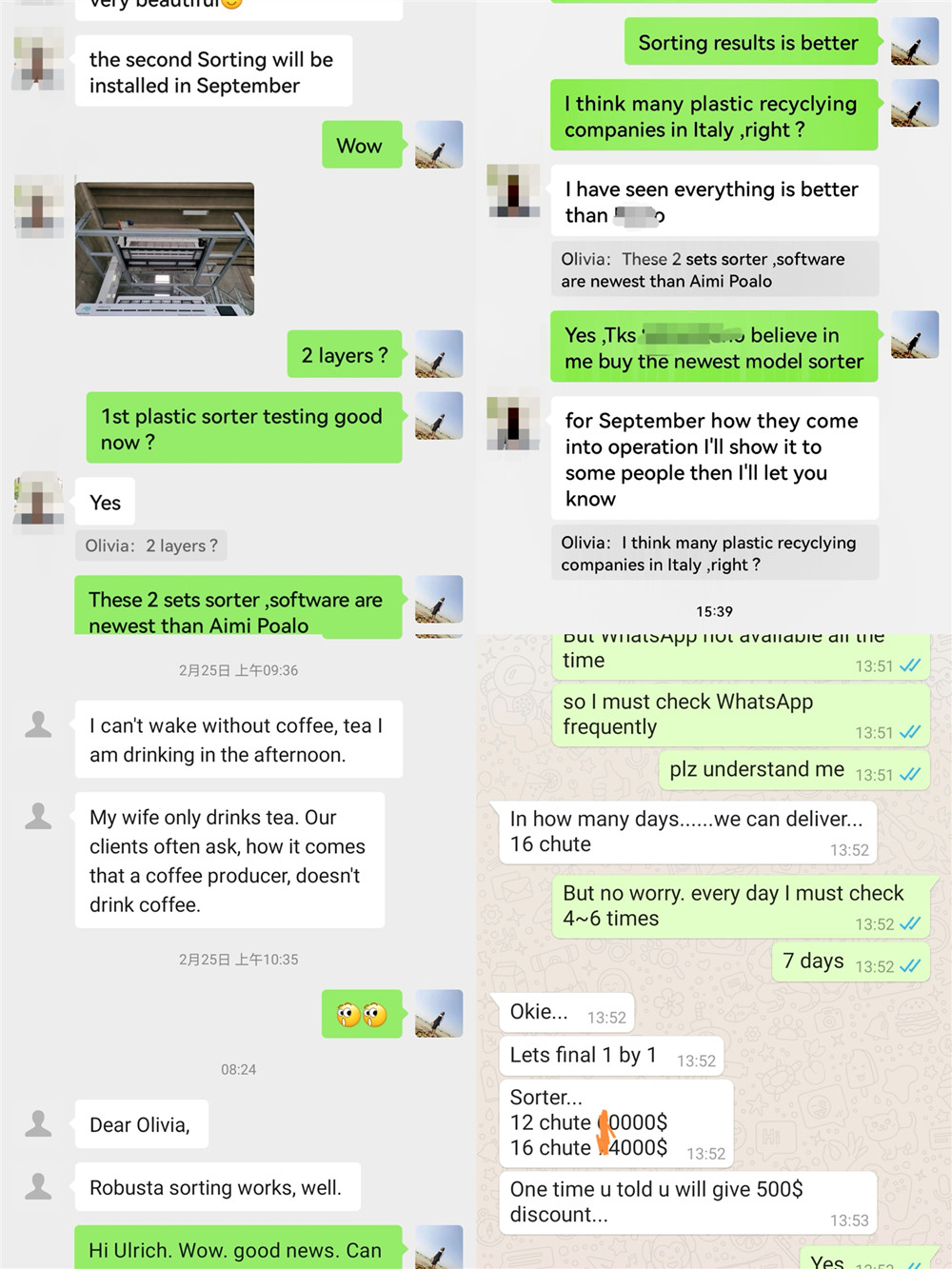

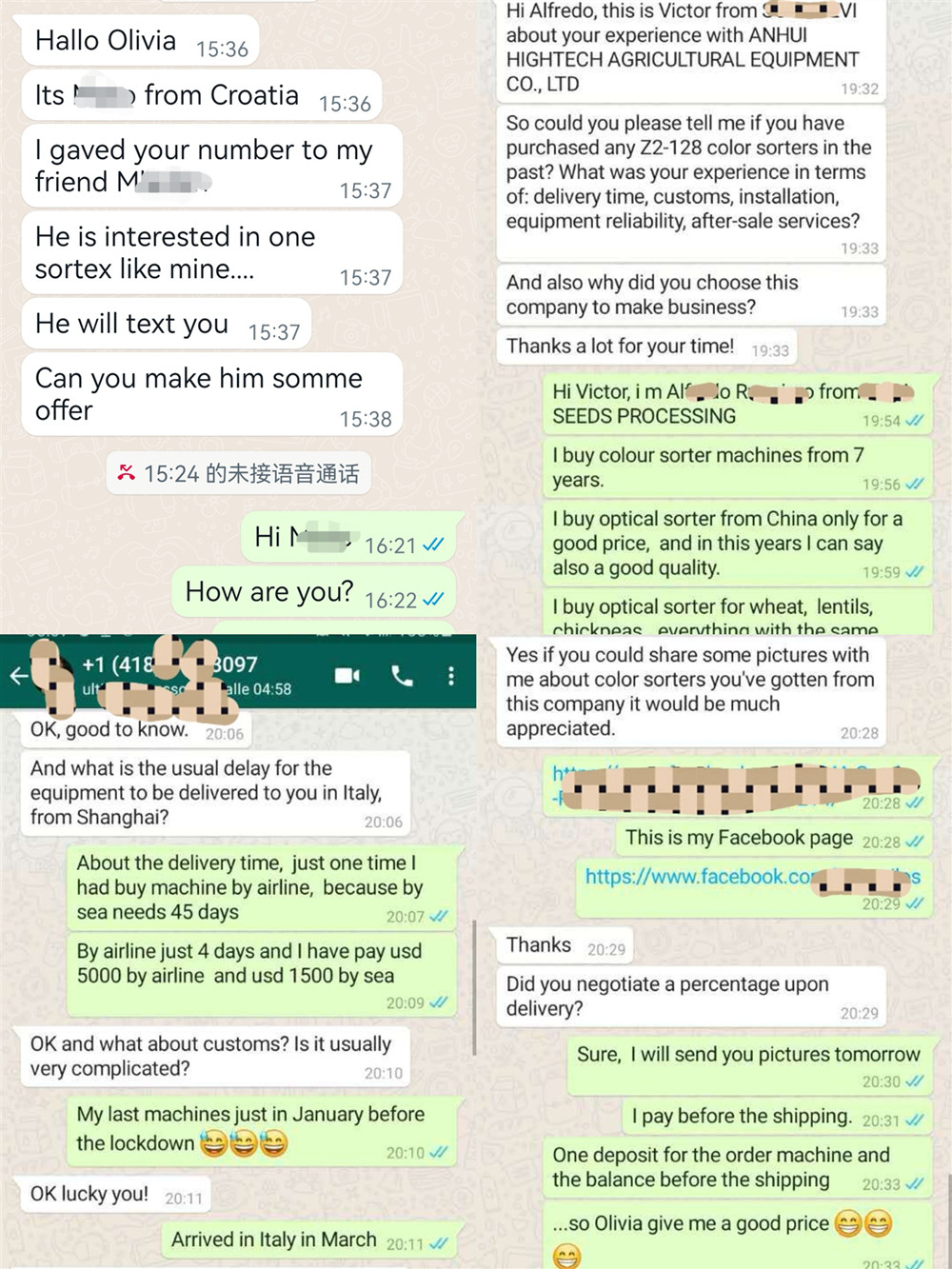

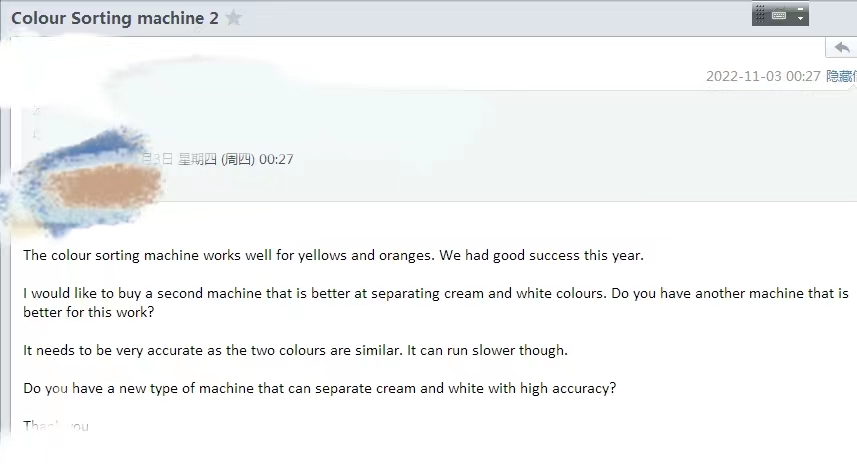

Customer feedback is the driving force behind our progress:

Plywood Case is Suitable for Sea/Road/Air Transport:

1. How to use the machine?

We will supply the Installation instructions and videos for guiding you how to set color sorter.

2. How long about the guarantee period?

Two years. And we supply lifelong software upgrade services for our customers.

3. Can you supply the air compressor, air tank and air filters?

Yes, we can provide above equipments, our standard offer includes color sorter machine with air compressor & air tank & air dryer & air filters.

4. Is oversea service available?

Yes, we will send engineer go abroad when you need it.

5.How to calculate Installation personnel cost?

On condition that customer requires to install, our company would like to send 1 engineer to guide for installation, then customer should to pay the cost, including transaction of engineer’s visa, transportation(air) for go abroad. and accommodation , local transportation and security when the engineer arrived.

6. If you have agent in our country?

We have agent in UK,New Zealand,Italy,Crotia,India, Guatemala,Finland,Malaysia,Bangladesh,Pakistan,Nigeria,Ukraine,Nicaragua etc. and we can provide after-sales service in your Country.

We have many installation cases and working videos.Please contact us freely if you need.