Payment:

T/T,L/CProduct Origin:

Hefei,ChinaShipping Port:

Shanghai / NingboLead Time:

Within 7-20 daysProduct Name:

Maize Color SorterWarranty:

2 yearsMachine Function:

Color/material/shape/size sortingCertificate:

CEThe Advantages And Applications Of Maize

Color Sorters In The Agricultural Industry

In today's competitive agricultural market, quality is paramount. Producers and processors are continually seeking ways to improve the quality of their products to meet consumer demands and regulatory standards. The maize color sorter has emerged as a key technological advancement in ensuring the highest quality maize output. By precisely sorting and grading maize based on color and other factors, these machines enhance efficiency and profitability. Let’s delve into how maize color sorters work, their applications, and the benefits they bring to users.

What Is A Corn Color Sorter?

Maize color sorters operate with incredible speed and accuracy, ensuring that only high-quality maize continues down the production line. By automating this sorting process, businesses can enhance productivity, reduce labor costs, and significantly improve the quality of their output.

Key Applications Of Maize Color Sorting Machine

Maize sorting machine have a broad range of applications, particularly within agricultural and food processing industries. Below are some of the key areas where maize color sorters prove invaluable:

1. Maize Processing And Packaging

During the processing of maize, foreign materials such as stones, plastic, and unwanted particles can be mixed in with the crop. Additionally, maize kernels can vary in color due to genetic factors, environmental conditions, or handling methods. The maize color sorter helps ensure uniformity in color and removes defective grains, contributing to better quality control in packaging processes.

2. Animal Feed Production

For manufacturers of animal feed, ensuring the nutritional quality of maize is essential. Maize colour sorter help by eliminating kernels that may be contaminated with toxins or mold, thus improving the safety of the feed and protecting the health of livestock.

3. Maize For Food Products

Maize is a key ingredient in numerous food products, from tortillas to cereals. Consumers expect high standards of quality in these products. The maize color sorting machines is indispensable in the food industry for ensuring only the best quality maize is used in food processing, enhancing the safety and visual appeal of the final products.

Benefits Of Using A Maize/Corn Color Sorter

Maize optical color sorters offer numerous benefits to agricultural processors, helping businesses improve efficiency, increase product quality, and reduce waste. Let’s explore the top benefits:

1. Enhanced Product Quality

One of the primary advantages of using a maize color sorter is the significant improvement in product quality. The machine's high-precision sensors can detect even the slightest color differences and remove defective grains that may affect the overall batch. This leads to a more uniform, visually appealing, and higher-grade product.

2. Increased Efficiency

Traditional manual sorting processes are time-consuming and prone to human error. Seed corn sorting machine, on the other hand, can process thousands of grains per minute with exceptional accuracy. This increases overall production efficiency and reduces labor costs, allowing businesses to scale their operations more effectively.

3. Reduction In Waste

Color sorter help reduce waste by identifying and removing only the defective or discolored maize kernels. The remaining good-quality maize is allowed to pass through the production process, ensuring less product is discarded. This is not only economically beneficial but also environmentally friendly, reducing overall food waste.

4. Improved Safety

Contaminated maize poses a significant risk to both human and animal health. Mold, toxins, or foreign materials in maize can lead to dangerous consequences if not properly sorted out. A maize color sorter can quickly identify and remove these contaminants, ensuring that only safe, high-quality maize reaches consumers.

5. Better Profit Margins

By increasing product quality and reducing waste, maize color sorters contribute to better profit margins for producers. The machine’s ability to accurately sort maize leads to higher-value products and less rejection from buyers due to quality issues.

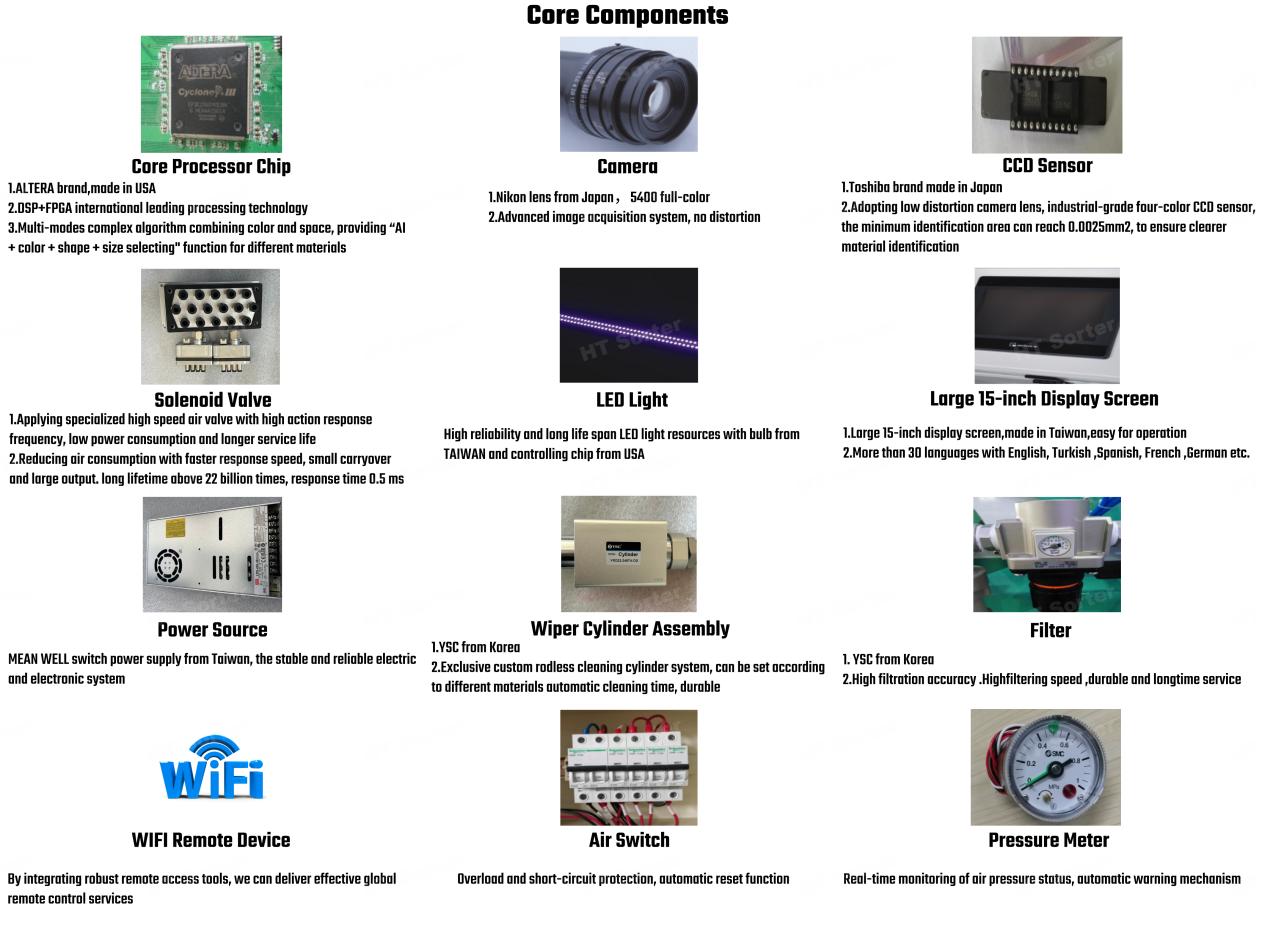

Technological Features Of Modern Maize Color Sorters

Modern maize color sorters are equipped with cutting-edge technology that makes them indispensable in today’s agricultural processing. Some of the standout features include:

High-ResolutionCameras: These capture images of each maize kernel, allowing for precise sorting based on color, shape, and size.

Advanced Software Algorithms: The software controlling the color sorter uses sophisticated algorithms to analyze images in real time, determining which kernels to keep or reject.

Multi-Lane Sorting: Many color sorters feature multiple lanes that allow for sorting at different levels of quality, further increasing the versatility of the machine.

Durable Design: Built for industrial use, modern maize color sorters are designed to handle large volumes of product with minimal maintenance, ensuring long-term reliability.

Conclusion

Maize color sorters have revolutionized the way maize is processed, providing a range of benefits for users including higher product quality, increased efficiency, reduced waste, and improved safety. Whether for food products, animal feed, or packaged maize, these machines ensure that only the best-quality kernels are sorted for further use. For businesses looking to enhance their processing capabilities and maximize profitability, investing in a maize (corn) color sorter is a smart, forward-thinking solution.

With the continuous advancement of technology, maize color sorters will continue to play a pivotal role in shaping the future of agricultural processing.

More Information About Color Sorter

Separate Materials By Color

Color sorters are intensively effective in sorting materials of different colors. Rice, grains, millets, and cereals are examples you might need to sort based on colors.

Separate Materials By Sizes

It is prevalent to sort foods by size. In general, a color sorter can sort products by sizes of 0.1mm to 100mm.

Separate Materials By Shapes

Sorting by shape is very useful to classify food like tea leaves and seafood. You can set the parameters you want and let the machine do the work.

Separate Materials By Types

In some cases, you might need to sort materials like nuts, seeds, and beans by type. To classify them efficiently and pick only the healthy ones.

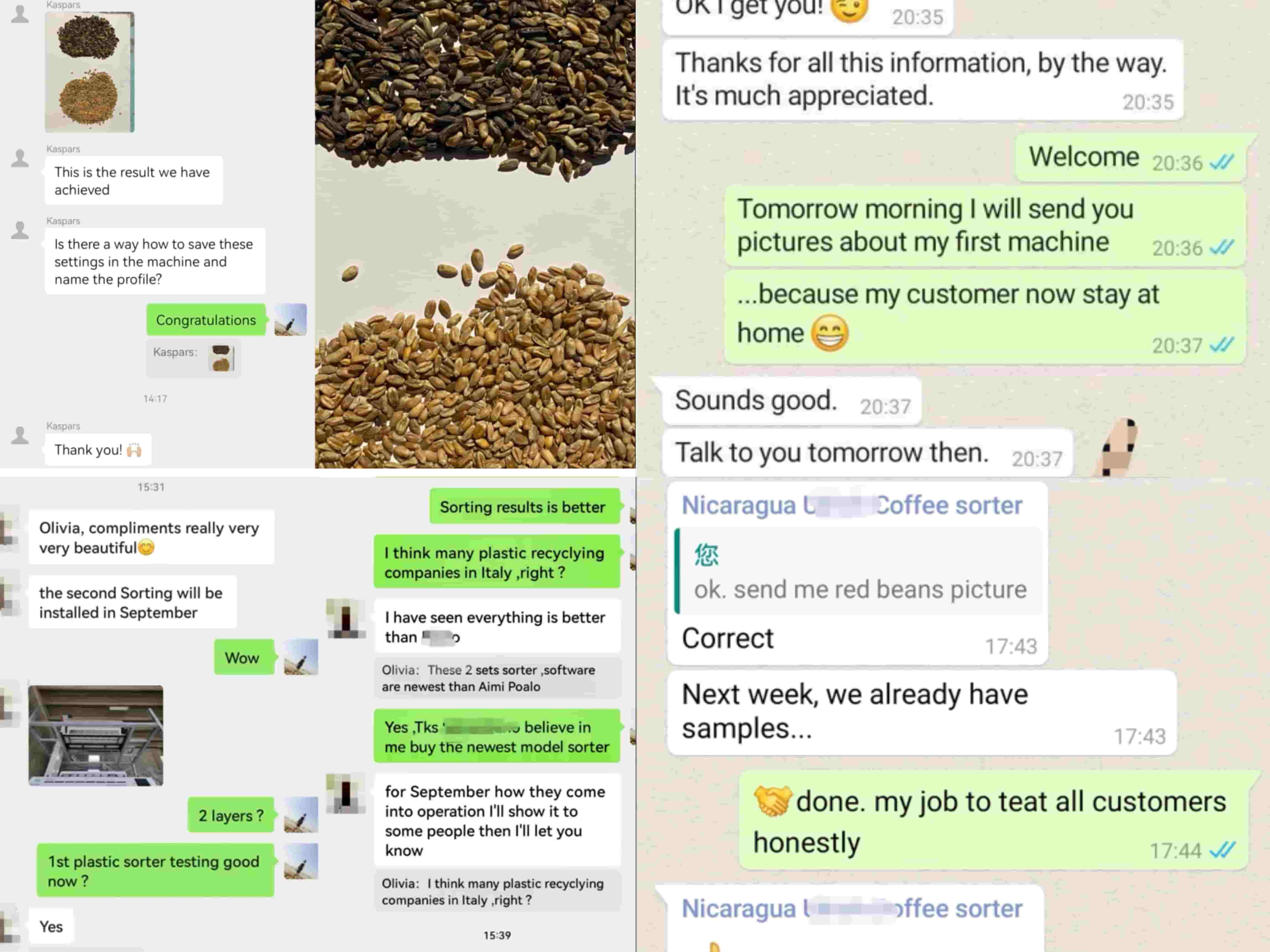

Customer Feedback Is The Driving Force Behind Our Progress

Sucessful Cases

Plywood Case Is Suitable For Sea/Road/Air Transport

Frequently Asked Questions By Customers

1. How to use the machine?

We will supply the Installation instructions and videos for guiding you how to set color sorter.

2. How long about the guarantee period?

Two years. And we supply lifelong software upgrade services for our customers.

3. Can you supply the air compressor, air tank and air filters?

Yes, we can provide above equipments, our standard offer includes color sorter machine with air compressor & air tank & air dryer & air filters.

4. Is oversea service available?

Yes, we will send engineer go abroad when you need it.

5.How to calculate Installation personnel cost?

On condition that customer requires to install, our company would like to send 1 engineer to guide for installation, then customer should to pay the cost, including transaction of engineer’s visa, transportation(air) for go abroad. and accommodation , local transportation and security when the engineer arrived.

6. If you have agent in our country?

We have agent in UK,New Zealand,Italy,Crotia,India, Guatemala,Finland,Malaysia,Bangladesh,Pakistan,Nigeria,Ukraine,Nicaragua etc. and we can provide after-sales service in your Country.

We have many installation cases and working videos.Please contact us freely if you need.