Item NO.:

HT3Order(MOQ):

1Payment:

T/T,L/CProduct Origin:

Hefei,ChinaShipping Port:

Shanghai / NingboLead Time:

Within 7-20 daysProduct Name:

Plastic color sorterWarranty:

2 yearsMachine Function:

Color/material/shape/size sortingCertificate:

CE

The recycling industry is undergoing a transformative shift with the integration of advanced plastic color sorter machines. These devices are revolutionizing the process of color sorting plastics, enhancing efficiency, quality, and sustainability. With the global emphasis on reducing plastic waste and promoting recycling, the importance of precise sorting techniques cannot be overstated. This article delves into the benefits of plastic color sorters and their significant impact on the recycling industry.

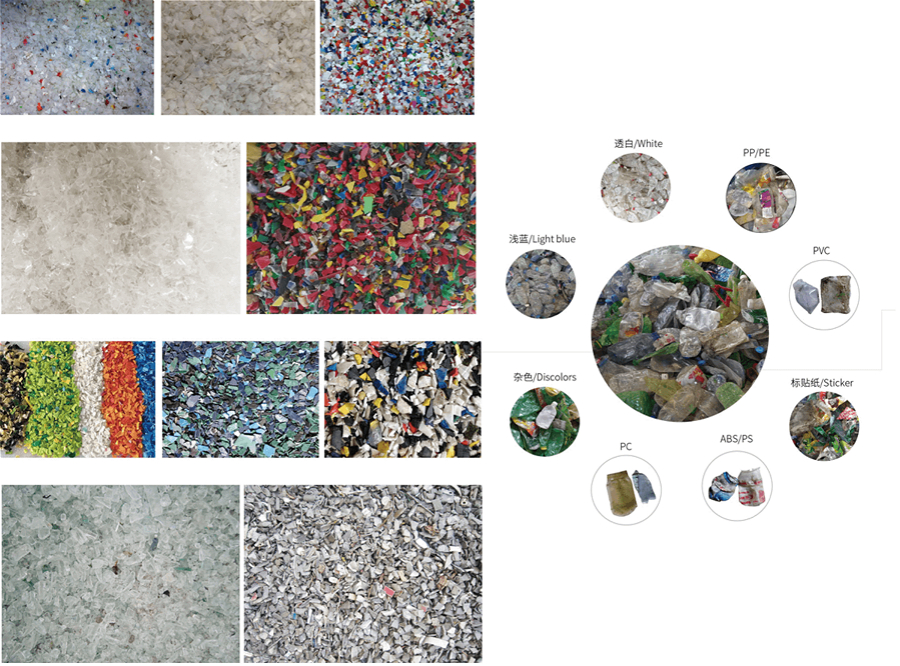

Plastic recycling presents unique challenges due to the diverse range of plastics in use. Different types of plastics—such as PET, HDPE, PVC, and more—often come in various colors, making manual sorting a daunting and inefficient task. Traditional methods relied on human labor to identify and separate plastics based on type and color, a process that was not only time-consuming but also prone to errors and inconsistencies.

Plastic color sorters utilize advanced optical and sensor technologies to automatically detect and sort plastics based on their color and materialso. These machines are equipped with high-resolution cameras, sensors, and sophisticated software that analyze the color and type of each plastic item as it passes through the sorter. The sorter then uses air jets or mechanical arms to separate the plastics into different categories.

Plastic Color Sorter Technical Dates

| Model |

MPCS3 |

MPCS5 |

MPCS7 |

|

Capacity(t/h) |

1-1.5 |

1.5-2.5 |

2.5-4 |

|

Number of Execution Units |

180 |

300 |

420 |

|

Size of Sorting(mm) |

2*2-30*30 |

2*2-30*30 |

2*2-30*30 |

|

Power(kw) |

1.8 |

2.4 |

3.5 |

|

Dimensions(L*W*H)(mm) |

1455*1597*2142 |

2075*1597*2142 |

2625*1597*2142 |

|

Weight(kg) |

940 |

1330 |

1650 |

Improved Efficiency Plastic color sorters drastically reduce the time required to sort plastics. Automated sorting allows for continuous operation, handling large volumes of plastics much faster than manual sorting. This efficiency is crucial for recycling facilities looking to process substantial quantities of plastic waste quickly.

Enhanced Accuracy and Consistency One of the primary advantages of plastic color sorters is their ability to deliver precise and consistent sorting results. The advanced sensors and algorithms used in these machines ensure that plastics are accurately categorized by color, reducing the likelihood of contamination in the sorted materials. This accuracy is essential for producing high-quality recycled plastics.

Increased Quality of Recycled Plastics By effectively separating plastics by color, plastic color sorters help produce purer batches of recycled material. This purity is vital for the recycling process, as mixed-color plastics can reduce the quality and value of the recycled products. High-quality recycled plastics are more desirable for manufacturers and can be used in a wider range of applications.

Cost Savings The efficiency and accuracy of plastic color sorters translate to significant cost savings for recycling facilities. Reduced labor costs, lower error rates, and increased throughput all contribute to a more cost-effective recycling process. Additionally, the higher quality of the sorted plastics can command better prices in the market.

Environmental Benefits Efficient plastic sorting leads to higher recycling rates, reducing the amount of plastic waste that ends up in landfills or the environment. By improving the quality of recycled plastics, these machines also support the creation of sustainable products, contributing to a circular economy. The overall reduction in plastic waste and increased use of recycled materials have substantial environmental benefits.

Scalability Plastic color sorters are scalable and can be integrated into recycling facilities of various sizes. Whether a small operation or a large industrial facility, these machines can be tailored to meet specific sorting needs, making them a versatile solution for the recycling industry.

The adoption of plastic color sorters is having a profound impact on the recycling industry. These machines are enabling facilities to meet the growing demand for high-quality recycled plastics, driven by both regulatory pressures and consumer demand for sustainable products. By enhancing the efficiency and accuracy of the sorting process, plastic color sorters are helping to make plastic recycling more economically viable and environmentally sustainable.

Future Developmen

The future of plastic color sorting technology looks promising, with ongoing advancements in artificial intelligence and machine learning expected to further enhance the capabilities of these machines. Future developments may include more sophisticated algorithms for identifying and sorting mixed plastics, as well as the integration of real-time data analytics for process optimization. Additionally, the combination of plastic color sorters with other recycling technologies, such as chemical recycling, could further improve the overall efficiency and effectiveness of plastic recycling.

Plastic color sorters are transforming the recycling industry by providing an efficient, accurate, and cost-effective solution for sorting plastics by color. These machines are playing a crucial role in enhancing the quality of recycled plastics, reducing environmental impact, and supporting the shift towards a more sustainable and circular economy. As technology continues to evolve, plastic color sorters will undoubtedly remain at the forefront of innovations in plastic recycling, driving further improvements in efficiency and sustainability.ts

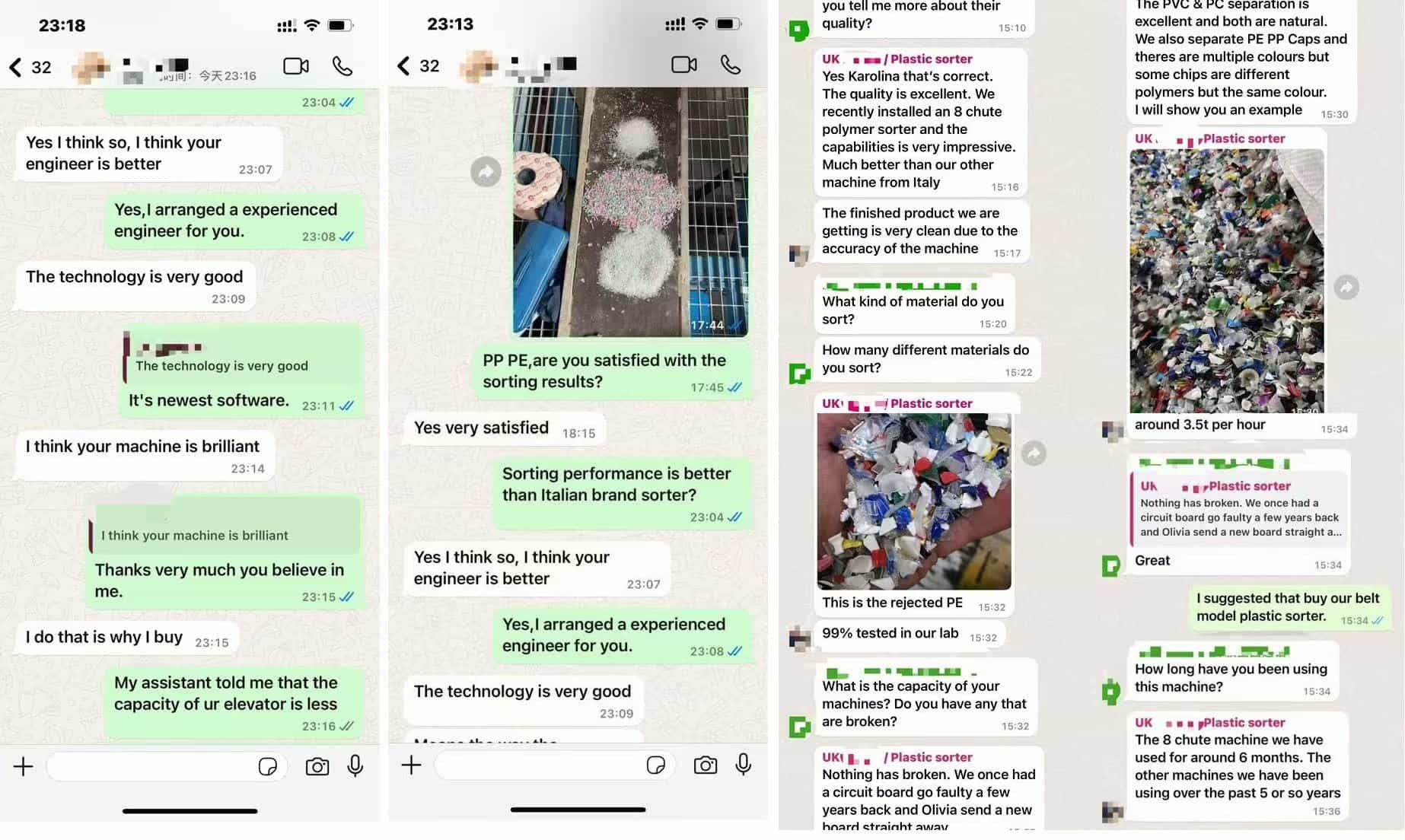

Customer Feedback Is The Driving Force Behind Our Progress

Sucessful Cases

Plywood Case Is Suitable For Sea/Road/Air Transport

1. How to use the machine?

We will supply the Installation instructions and videos for guiding you how to set color sorter.

2. How long about the guarantee period?

Two years. And we supply lifelong software upgrade services for our customers.

3. Can you supply the air compressor, air tank and air filters?

Yes, we can provide above equipments, our standard offer includes color sorter machine with air compressor & air tank & air dryer & air filters.

4. Is oversea service available?

Yes, we will send engineer go abroad when you need it.

5.How to calculate Installation personnel cost?

On condition that customer requires to install, our company would like to send 1 engineer to guide for installation, then customer should to pay the cost, including transaction of engineer’s visa, transportation(air) for go abroad. and accommodation , local transportation and security when the engineer arrived.

6. If you have agent in our country?

We have agent in UK,New Zealand,Italy,Crotia,India, Guatemala,Finland,Malaysia,Bangladesh,Pakistan,Nigeria,Ukraine,Nicaragua etc. and we can provide after-sales service in your Country.