Payment:

T/T,L/CProduct Origin:

Hefei,ChinaShipping Port:

Shanghai / NingboLead Time:

Within 7-20 daysProduct Name:

Plastic Electrostatic SeparatorWarranty:

2 yearsMachine Function:

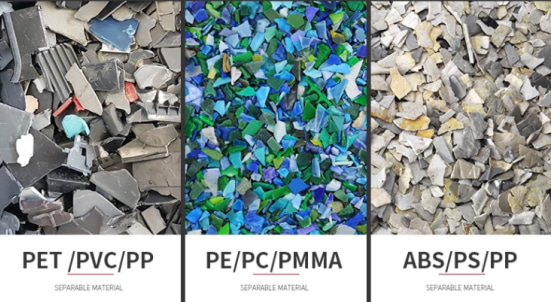

Plastic materials sortingCertificate:

CEWe can offer a recycling plant ,from heating conveyor, rubber separator to electrostatic separator machine ( plastic recycling machines) and color sorter machine.

Technology Parameters

|

Name |

Model |

Capacity |

Size |

Power |

|

Plastic Electrostatic Separator |

R500 |

0.5-0.8T/h |

3.5x2.5x5.75m |

9KW |

|

Plastic Electrostatic Separator |

R1500 |

1.0-1.5T/h |

4.0x3.0x5.75m |

11KW |

|

Plastic Electrostatic Separator |

R3000 |

2.0-3.0T/h |

4.5x3.5x5.75m |

12.5KW |

|

Plastic Electrostatic Separator |

R5000 |

4.0-5.0T/h |

4.5x3.5x5.75m |

30KW |