Payment:

T/T,L/CProduct Origin:

Hefei,ChinaShipping Port:

Shanghai / NingboLead Time:

Within 7-20 daysProduct Name:

Peanuts colour sorterWarranty:

2 yearsMachine Function:

Color/material/shape/size sortingCertificate:

CEIncrease Your Farm's Profits with a Peanut Color Sorter

Introduction: Peanuts are a popular crop grown in many parts of the world, but sorting them by hand can be a time-consuming and labor-intensive process. Fortunately, peanut color sorters provide a more efficient and cost-effective way to sort peanuts based on their color and quality. In this article, we'll discuss how peanut color sorters work and how they can help farms increase their profits.

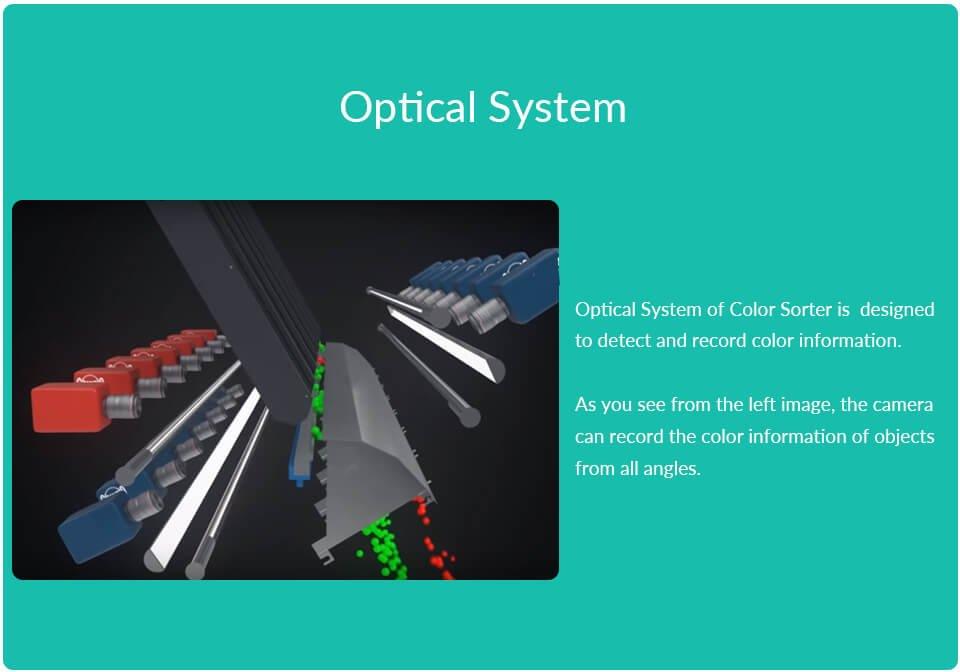

How Peanut Color Sorters Work: Peanut color sorters use advanced imaging technology to sort peanuts based on their color and quality. The machine uses a high-speed camera and sophisticated software algorithms to capture images of each peanut as it passes through the sorting process. The software analyzes the images and identifies any defects or impurities, such as discolored or damaged peanuts.

Once identified, the machine separates the defective peanuts from the good ones using a series of air jets or mechanical arms. This results in a batch of high-quality, uniformly colored peanuts that are ready for further processing or packaging.

Advantages:

1.Increased Efficiency: Sorting peanuts by hand can be a time-consuming and labor-intensive process. Peanut color sorters can sort peanuts at a much faster rate, resulting in a more efficient sorting process and faster turnaround times.

2.Improved Quality: Peanut color sorters can identify and remove defective or impure peanuts, resulting in a higher quality batch of peanuts that are more desirable to buyers.

3.Cost Savings: By automating the sorting process, peanut color sorters can reduce labor costs and improve the overall profitability of a farm.

4.Customizable Options: Peanut color sorters can be customized to meet the specific needs of a farm, ensuring that they get the most out of their investment.

5.How Peanut Color Sorters Help Farms Increase Their Profits: Investing in a peanut color sorter can help farms increase their profits in several ways. First, by improving the quality of their peanuts, farms can command a higher price from buyers. Second, peanut color sorters can reduce the amount of waste and rejected peanuts, resulting in a higher yield and increased profits. Finally, peanut color sorters can increase the efficiency of the sorting process, resulting in faster turnaround times and increased production capacity.

Conclusion: If you're a peanut farmer looking to increase your profits, investing in a peanut color sorter is a smart choice. With its advanced imaging technology and efficient sorting process, a peanut color sorter can improve the quality of your peanuts, reduce waste, and increase your production capacity, resulting in higher profits for your farm. Contact us today to learn more about how a peanut color sorter can benefit your business.

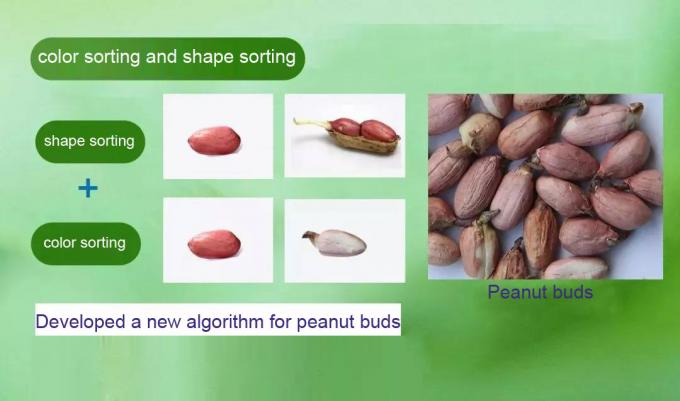

The optical sorting of bud has always been a problem that the industry needs to overcome, especially the bud below 3mm. The traditional color sorter has a certain recognition ability to recognize more than 3mm and colored long buds, but it is almost not selected for short buds of the same color below 3mm. HIGHTECH CCD pioneered the intelligent quality selection technology of bud, high-dimensional image acquisition and fusion positioning analysis, combined with the cloud brain integrated algorithm, to accurately select all kinds of same color and different color bud heads.

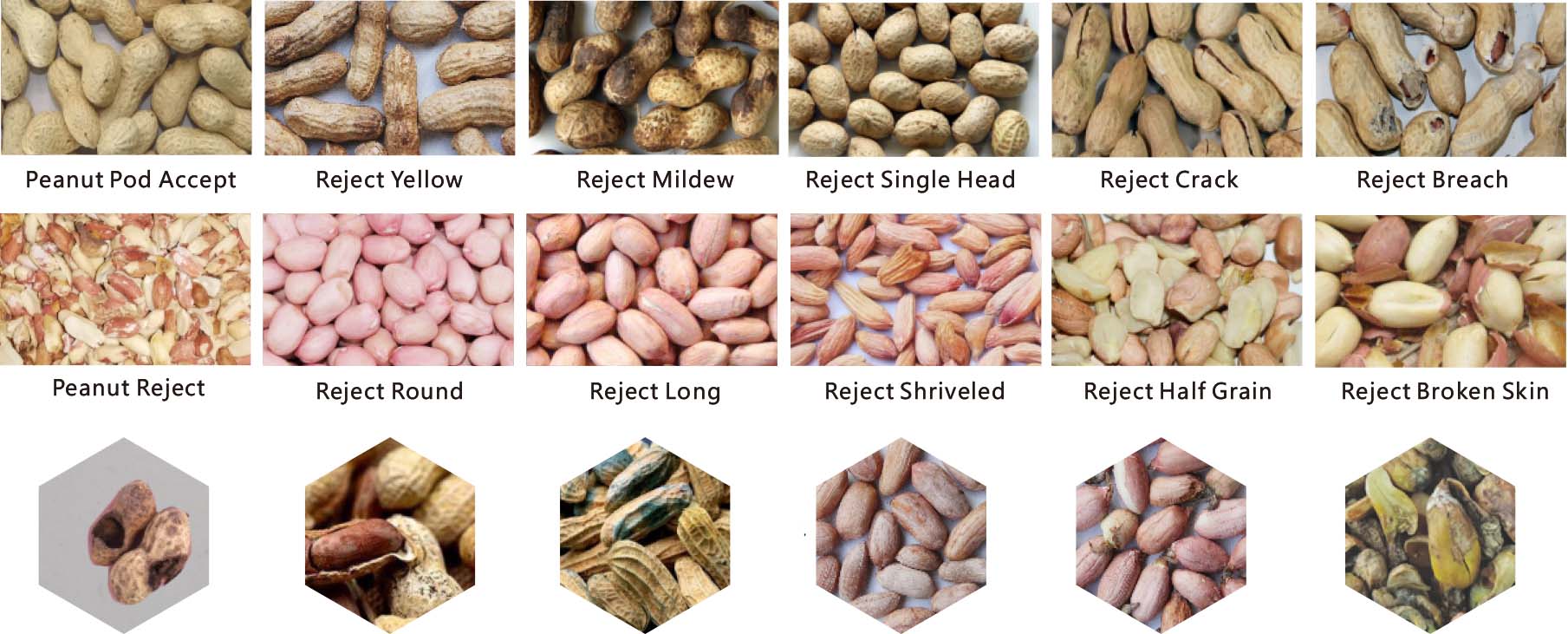

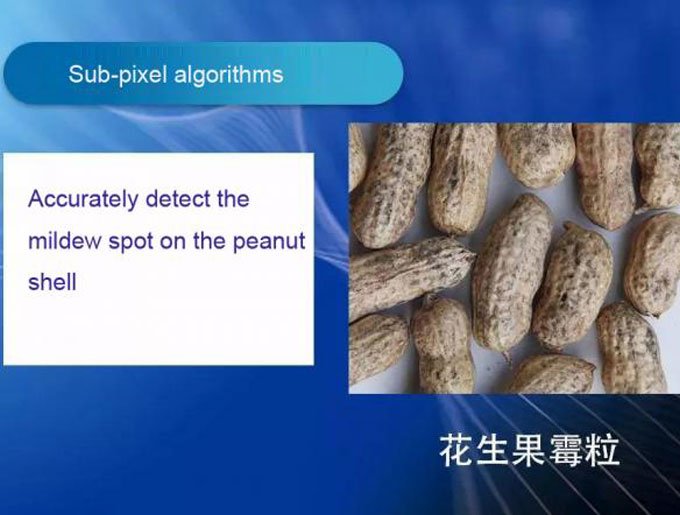

The CCD Peanut Color Sorter can detect and remove visible defects such as stones,grass,nut grass,stalks,stems,raisins,shells,

discoloration,soy,bones,wood,corn,glass,and in shell as well as invisible to the human eye defects such as aflatoxin.

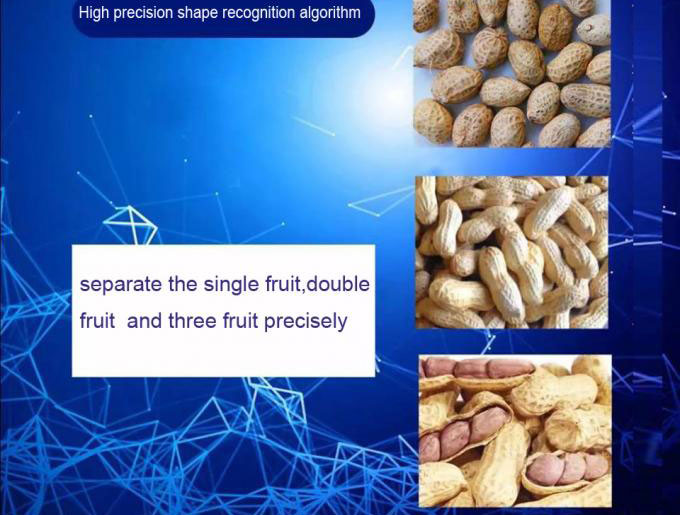

Bionic four-color recognition technology, intelligently identify moldy, yellow rust, gray rust, insect erosion, frozen, diseased and other bad products; intelligent shape selection recognition technology, easy to classify the same diameter oval, length, size , Thickness, fat and thin peanuts of different shapes.

High-dimensional three-dimensional material fingerprint fingerprint sensing technology, high-dimensional holographic collection and analysis of the characteristic fingerprint information of the selected material, ultra-precise removal of glass, plastic, stone, soil, straw, animal feces, shells, slag and other malignant impurities, comprehensive protection of finished products quality.

|

Model |

Output(T/H) |

Carryover |

Power(KW) |

Voltage |

Weight(kg) |

Dimension(mm) |

|

MPS1 |

0.5-3 |

>10:1 |

0.3-0.5 |

220V/50HZ |

240 |

975*1550*1400 |

|

MPS2 |

1-6 |

>10:1 |

0.4-0.65 |

220V/50HZ |

500 |

1240*1705*1828 |

|

MPS3 |

1.5-9 |

>10:1 |

0.7-1.1 |

220V/50HZ |

800 |

1555*1707*1828 |

|

MPS4 |

2-12 |

>10:1 |

0.7-1.1 |

220V/50HZ |

1000 |

1869*1707*1828 |

|

MPS5 |

2.5-15 |

>10:1 |

0.7-1.1 |

220V/50HZ |

1100 |

2184*1707*1828 |

|

MPS6 |

3-18 |

>10:1 |

1.1-1.9 |

220V/50HZ |

1350 |

2500*1707*1828 |

|

MPS7 |

3.5-21 |

>10:1 |

1.1-1.9 |

220V/50HZ |

1350 |

2814*1707*1828 |

|

MPS8 |

2.5-15 |

>10:1 |

1.3-2.2 |

220V/50HZ |

1500 |

3129*1707*1828 |

|

MPS10 |

5-30 |

>10:1 |

1.4-2.3 |

220V/50HZ |

1750 |

3759*1710*1828 |

|

MPS12 |

4-25 |

>10:1 |

1.4-2.3 |

220V/50HZ |

1900 |

4389*1710*1828 |

From optical sorting to color vision sorting,and then to multidimensional fusion sorting. From computational intelligence to perceptual intelligence, and then to the iteration of cognitive intelligence, every technological revolution of HT is changing the world we are familiar with.

HT has grown for more than 20 years, and has gone deep into the processing industries such as beans, seeds,nuts, wheat and grains, focusing on advanced technical research on material sorting. HT' S new series of deep learning equipment brings multiple value experiences to customers for multi scenario applications.

New intelligent algorithm & communication architecture,AI deep self-learning

Hardware platform architecture,standardization, modularization,high stability and low failure rate

The effect is not trivial,output increased by 15%,the accuracy is increased by 10%,bring out ratio reduced by 20% .

Pure and extraordinary sorting performance

Expandable design can be equipped with multi-dimensional cameras.

Network cloud platform

Realize real-time data monitoring

1,Increased yield

2,Reduced labor requirements

3,Increased throughput

4,Consistent quality

Our peanut sorting solutions boost throughput and availability while at the same time increasing yield,quality and food safety