Payment:

T/T,L/CProduct Origin:

Hefei,ChinaShipping Port:

Shanghai / NingboLead Time:

Within 7-20 daysWarranty:

2 yearsCertificate:

CEQuartz magnetic separator

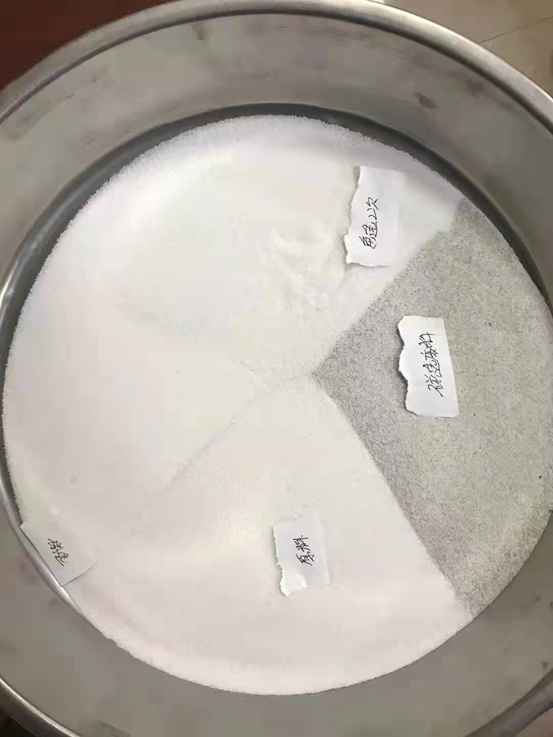

It’s suitable for iron removal and purification of non-metallic minerals such as quartz sand, potash feldspar, nepheline and kaolin, and also for magnetic product separation and recovery of metallic minerals such as hematite, limonite, manganese ore, wolfram, tantalum and niobium.

Empowered with rich industrial experienced staffs and engineers group, we are engaged in offering the huge range of Quartz Magnetic Separator. These offered Quartz Magnetic Separator are used to extract the iron ore from the minerals .

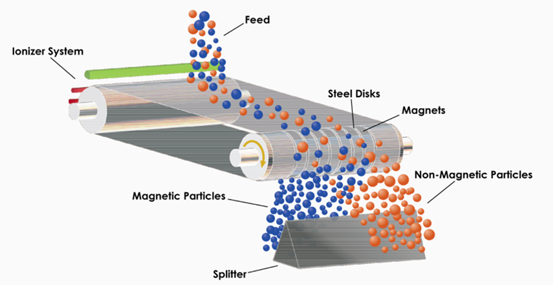

How does it work?

The slurry enters the feeding box and flows out evenly on the belt with a thin layer through the bottom holes. The magnetic particles in the slurry are captured by the magnetic force of the magnetic system under the belt and adsorbed on the upper surface of the belt.Then the magnetic particles are intercepted by the raised rubber strip on the belt and moves upward with the belt.When it arrived the rinsingMineral processing is a major division in the science of extractive metallurgy. extractive metallurgy has been defined as the science and art of extracting metals from their ores, refining them and preparing them for use. Within extractive metallurgy, the major divisions in the order they may most commonly occur are, mineral processing (or beneficiation), hydrometallurgy, pyrometallurgy, and electrometallurgy. the last steps in the winning of metals are in physical metallurgy where the composition and treatment of metals are varied to provide desired physical and mechanical properties.

Quartz sand magnetic separator or are developed for wet separation of magnetite, iron pyrites, hematite, ilmenite… with particle size below 6mm and are also suitable for removing iron from coal, nonmetal minerals, construction materials and for heavy magnetite recovery.

Also here we use specially developed and produced by high energy magnets, guaranteeing highest field gradient and highest magnetic force.

Following executions are available both as standard and specially developed based on customer requirements:

CTS: Concurrent tank: high recovery system for particles size below 6mm

CTB: Self-leveling counter-rotation tank: medium recovery system for particles size below 1mm

CTN: Counter-rotation tank: low recovery system for particle size below o.6mm

For maximum separation capacity Double or Triple Roller systems can be used

We are engaged in offering the huge range of magnetic ore separator. these offered quartz magnetic separators are used to extract the iron ore from the minerals which are hard in form and looks shiny crystal. quartz is a mineral composed of silicon and oxygen atoms in a continuous framework of sio₄ silicon–oxygen tetrahedra, with each oxygen being shared between two tetrahedra, giving an overall chemical formula of sio₂. moreover the separator is used to remove the rubbish iron from the mineral.

| Features of Quartz sand magnetic separator: |

| 1.Metal Separator has high magnetic recovery and discharge. |

| 2. The feed slurries recover the magnetics. |

| 3. Available in single or multiple drum applications. |

| 4. Recover magnetic solids in as clean a magnetic concentrate as possible. |

| 5. Permanent magnet assembly eliminates coil burn-outs. |

| 6. The magnet / pole elements are bolted to a mild steel shaft. |

| 7. The drum is made from thick stainless steel for long service life. |

|

Model |

WG160B-V-3 |

WG220B-V-3 |

WG300-V-7 |

WG220B-V-11 |

WG430-V-11 |

WG220-V-15 |

WG600-V-20 |

|

Magnetic field strength(t) |

2 |

2 |

3 |

3 |

3 |

5 |

3 |

|

Input voltage(VAC) |

380 |

220 |

380 |

380 |

380 |

380 |

380 |

|

Maximun output current(A) |

15 |

7 |

20 |

20 |

20 |

30 |

40 |

|

Maximum coil power(KW) |

3 |

3 |

7 |

11 |

11 |

15 |

20 |

|

Insulation category |

E |

E |

E |

E |

E |

E |

E |

|

Cooling method |

water and oil cooling |

water and oil cooling |

water and oil cooling |

water and oil cooling |

water and oil cooling |

water and oil cooling |

water and oil cooling |

|

Magnetic lumen diameter(mm) |

160 |

220 |

300 |

220 |

430 |

220 |

600 |

|

Yield(m3/h) |

0.5-1.5 |

43833 |

1.5-4 |

0.5-3 |

1.5-6 |

1-3 |

3-8 |

|

Dimension(mm) |

700*700 |

860*860 |

1320*1320 |

1300*110 |

1500*1500 |

1350*1100 |

1500*1500 |

|

*1450 |

*1540 |

*2500 |

*1800 |

*2500 |

*1850 |

*2000 |

|

|

Main machine weight(kg) |

450 |

490 |

1020 |

1130 |

1210 |

1500 |

2000 |

|

Usage |

60-300 mesh feedstock of iron elimination |

||||||