Payment:

T/T,L/CProduct Origin:

Hefei,ChinaShipping Port:

Shanghai / NingboLead Time:

Within 7-20 daysProduct Name:

Rice color sorterWarranty:

2 yearsMachine Function:

Color/material/shape/size sortingCertificate:

CERice is a staple food for millions of people around the world, and its quality is a critical factor for both farmers and consumers. However, traditional sorting methods for rice can be slow, inconsistent, and labor-intensive. That's where rice color sorting machines come in. These machines use advanced imaging technology to sort rice based on its color, shape, and texture. In this article, we'll explore how rice color sorting machines work and the advantages they offer for rice processing.

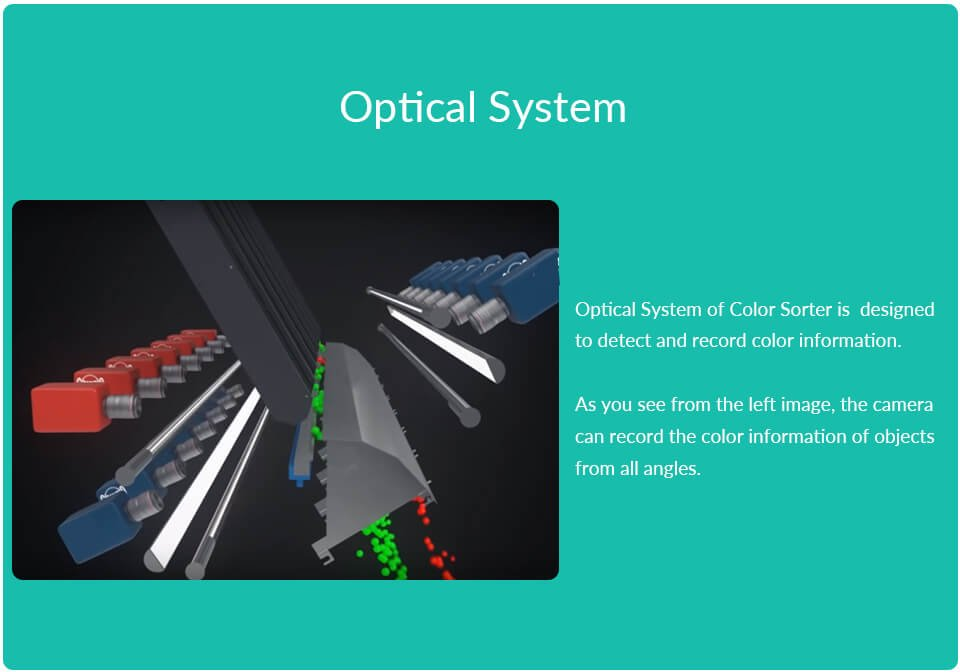

How Rice Color Sorting Machines Work: Rice color sorting machines use high-speed cameras and advanced software algorithms to capture images of each individual rice grain as it passes through the sorting process. The software analyzes the images and identifies any defects or impurities, such as broken grains, discolored grains, and foreign material.

Once identified, the machine separates the defective grains from the good ones using a series of air jets or mechanical arms. This results in a batch of high-quality, uniformly colored rice grains that are ready for further processing or packaging.

Advantages:

1.Improved Quality: Rice color sorting machines can identify and remove defective or impure grains, resulting in a higher quality batch of rice that is more desirable to buyers.

2.Increased Efficiency: Sorting rice by hand can be a time-consuming and labor-intensive process. Rice color sorting machines can sort rice at a much faster rate, resulting in a more efficient sorting process and faster turnaround times.

3.Cost Savings: By automating the sorting process, rice color sorting machines can reduce labor costs and improve the overall profitability of a processing operation.

4.Customizable Options: Rice color sorting machines can be customized to meet the specific needs of a processing operation, ensuring that they get the most out of their investment.

5.How Rice Color Sorting Machines Help Rice Processing: Investing in a rice color sorting machine can help rice processing operations increase their profits in several ways. First, by improving the quality of their rice, processing operations can command a higher price from buyers. Second, rice color sorting machines can reduce the amount of waste and rejected rice grains, resulting in a higher yield and increased profits. Finally, rice color sorting machines can increase the efficiency of the sorting process, resulting in faster turnaround times and increased production capacity.

Conclusion: If you're in the rice processing industry and looking to improve your efficiency and profitability, investing in a rice color sorting machine is a smart choice. With its advanced imaging technology and efficient sorting process, a rice color sorting machine can improve the quality of your rice, reduce waste, and increase your production capacity, resulting in higher profits for your business. Contact us today to learn more about how a rice color sorting machine can benefit your rice processing operation.

Characteristics

1) The min. identify can be up to 0.04 mm2 , makes color sorting reach a new high level, meets demand of accurate sorting.

2) Advanced and Reasonable optics design guarantees accurate sorting.

3) Double sorting process guarantees final ideal sorting result.

4) Reasonable channel assigns suitable for sorting grain with various size.

5) Advanced production equipments from Germany and strict management under ISO9001:2008 guarantees machines' precision.

6) Great Data transferring Bandwidth guarantees the data transferred rapidly, makes machine perform consistently and stably.

7) Latest Patented technology of image processing algorithm upgrades the accuracy, and accelerates the operation speed.

8) Several sorting modes meet various requirements.

9) Advanced system design with China Patent guarantees machine run stably for a long time.

10) Concise touch panel from Japan helps customer operate easily

Parameter Table

| Model | R1-64 | R2-128 | R2-192 | R4-256 | R5-320 | R6-384 | R7-448 | R10-640 | R12-768 |

| Type | 6SXM-64 | 6SXM-128 | 6SXM-192 | 6SXM-256 | 6SXM-320 | 6SXM-384 | 6SXM-448 | 6SXM-640 | 6SXM-768 |

| Output(t/h) | 0.5-1 | 1.5-4 | 3-6 | 5-10 | 6-10 | 7-12 | 8-15 | 13-24 | 18-30 |

| Sorting Accuarcy(%) | ≥99.99 | ≥99.99 | ≥99.99 | ≥99.99 | ≥99.99 | ≥99.99 | ≥99.99 | ≥99.99 | ≥99.99 |

| Optimized Carryover (Bad:Good) | ≥20:1 | ≥20:1 | ≥20:1 | ≥20:1 | ≥20:1 | ≥20:1 | ≥20:1 | ≥20:1 | ≥20:1 |

| Weight (kg) | 400 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1400 | 1600 |

| Resolution(mm2) | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 |

| Power(kw) | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 4.0 | 4.5 | 6.0 | 8.0 |

| Dimensions (LxWxH)(mm) | 1070*1650 x2010 |

1370x1650 x2010 |

1684x1650 x2010 |

1998x1650 x2010 |

2312x1650 x2010 |

2626x1650 x2010 |

2930x1650 x2010 |

4100x1650 x2010 |

2670x3000 x2010 |

| Power Supply(V/Hz) | 220/50 (110/60) |

220/50 (110/60) |

220/50 (110/60) |

220/50 (110/60) |

220/50 (110/60) |

220/50 (110/60) |

220/50 (110/60) |

220/50 (110/60) |

220/50 (110/60) |

1. The above data is based on the 2% contamination, and real output depends on the material and its contamination.

2. If products update, no further notice. Please refer to the real machine.

Advantages of newest model rice color sorter machine

Inheriting 20 years of professional quality accumulation in HT 13 core technologies are blessed, stronger applicability, and more durable.

One machine has multiple sorting models, which can easily control the sorting needs of different colors, yellow, whites and other process points, and perfectly create cost-effective sorting of popular items.

It is your quality choice!

Inheriting the excellent characteristics of RG products, the intelligent technology continues to evolve, the uniform feeding technology, intelligent early warning technology and other comprehensive upgrades, while more intelligent, the sorting and protection algorithm is continuously optimized, the sorting of yellow and white is more accurate, the finished product is better,and the by-products are more valuable. Intelligent evolution,excellent choice!

In response to the design needs of the process points of crushing,mutual mixing and sorting,and miscellaneous impurities sorting, RG+ product innovation adopts HT S-class professional identification system to integrate composite infrared spectrum, iteratively presents dual spectrum + dual composite technology, and opens up "color +shape+ Material" Three-dimensional integration era; realize multi-dimensional and multi-feature identification such as color, shape, texture,size, area, weight, soft and hard, and continuously optimize the sorting effect, bringing excellent user experience. Keep improving, iterative choice!

Intelligent Image Recognition

Hundreds of professional identification algorithms, integrated with

the third-generation multispectral confocal technology,realize multi-dimensional and multi-feature learning such as color,

shape, texture, area, weight, soft and hard, etc.

Continuous perception, improvement, and data iteration, the road is

simple, and the recognition is infinite;

Ai Smart Sorting

One- click smart selection, smart simulation technology,

real-time dynamic online tracking,bring the ultimate operating experience;

Cloud Think Tank

HT invested to build an open mass sorting application database,

Cloud interactive storage, a wide range of material solutions arel

exclusively created for you,share the convenience and value of the big data era with users.

Intelligent Care System

Feeding protection + soft landing buffer design, detail protection, sincerely for you;

Balanced Feeding

Intelligent analysis adaptive material level flow rate system,balance the flow of the production line to ensure the best sorting effect, better production capacity, and unattended;

Intellectual Defense Guard

Multiple intelligent early warning protection,no worries about equipment operation, unlimited distance,serve us everywhere;

Super Alloy High Frequency Solenoid Valve

National patent, high frequency and low air consumption,wear-resistant and high-temperature superalloy, matching for lifetime;

Breathable Bionic Wind Net System

Engineering bionic design, intelligent breathing air network system, multi-directional separation design, non-stop cleaning,more thorough cleaning;

Powerful Chips

HT Smart DGS chip and ARM work together, dual-core + dual intelligent engine, the operation efficiency is geometrically improved, higher speed, more efficient and smarter, to meet the user's requirements for different material characteristics,impurities, and quality standards changes, HT dedicate a shocking sorting experience to the forward-looking.

All Things Connected

Real-time online HT cloud platform, remote interconnection, control, maintenance,early warning, upgrade, operation and maintenance data, intelligent online inspection etc , can easily have real-time services, your exclusive online nanny.

Examples Of Sorting

The flow is streamlined and scanned by the sorter’s SSD sensors. Once the camera detects a color defect, it instructs ejectors that are machine-fitted to open a nozzle connected to valves with compressed air. The air then shoots the defected rice out the types of rice defected include:

Packaging & Shipping

Machines to be carefully packaged to endure transportation under harsh conditions. Handling instructions are designed to protect the machine in the critical moments during transportation, unloading and installation.

Delivery Time: 10- 20 Days after order confirmed.

Payment Terms: TT, Letter of Credit.

Commissioning and Installation

1. On Site Installation and Training Service by our professional engineer ;

2. Study and Learn the Machine Operation in Our Factory.

3. Responsive in 24 hours: Telephone, Email, Video or On Site Solutions by our Technical Experts.

More information about color sorter

Separate Materials By Color

Color sorters are intensively effective in sorting materials of different colors. Rice, grains, millets, and cereals are examples you might need to sort based on colors.

Separate Materials By Sizes

It is prevalent to sort foods by size. In general, a color sorter can sort products by sizes of 0.1mm to 100mm.

Separate Materials By Shapes

Sorting by shape is very useful to classify food like tea leaves and seafood. You can set the parameters you want and let the machine do the work.

Separate Materials By Types

In some cases, you might need to sort materials like nuts, seeds, and beans by type. To classify them efficiently and pick only the healthy ones.

Customer feedback is the driving force behind our progress:

Plywood Case is Suitable for Sea/Road/Air Transport:

1. How to use the machine?

We will supply the Installation instructions and videos for guiding you how to set color sorter.

2. How long about the guarantee period?

Two years. And we supply lifelong software upgrade services for our customers.

3. Can you supply the air compressor, air tank and air filters?

Yes, we can provide above equipments, our standard offer includes color sorter machine with air compressor & air tank & air dryer & air filters.

4. Is oversea service available?

Yes, we will send engineer go abroad when you need it.

5.How to calculate Installation personnel cost?

On condition that customer requires to install, our company would like to send 1 engineer to guide for installation, then customer should to pay the cost, including transaction of engineer’s visa, transportation(air) for go abroad. and accommodation , local transportation and security when the engineer arrived.

6. If you have agent in our country?

We have agent in UK,New Zealand,Italy,Crotia,India, Guatemala,Finland,Malaysia,Bangladesh,Pakistan,Nigeria,Ukraine,Nicaragua etc. and we can provide after-sales service in your Country.

We have many installation cases and working videos.Please contact us freely if you need.