World's First AI-Powered Polymer Sorter Helps Plastics Recycling Industry Move Toward Carbon Neutrality

The global recycled plastics market will reach $62 billion in 2024, with a compound annual growth rate of over 18% for high-efficiency sorting equipment. With the new EU regulations requiring the proportion of recycled plastic packaging materials to reach 55% in 2030, and China's “dual carbon” policy continues to increase, the intelligent Plastic Sorting Machine has become the core equipment to open up the “waste plastic recycling - high-end manufacturing” value chain. The intelligent Plastic Sorting Machine has become the core equipment to connect the value chain of “plastic recycling and high-end manufacturing”.

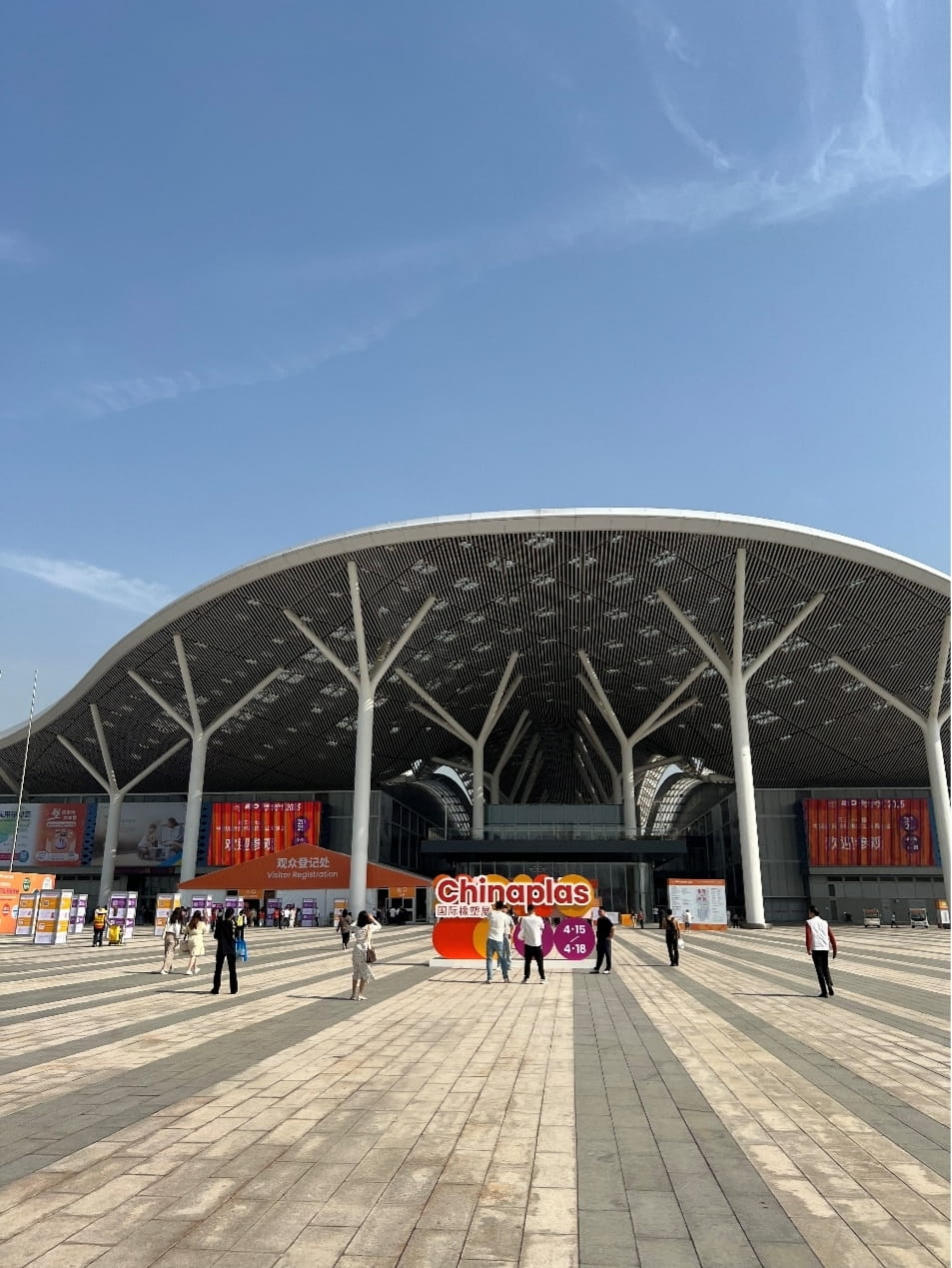

April 15-18, 2025, the global plastics industry attention of the 39th ** Shenzhen International Rubber and Plastics Exhibition (CHINAPLAS) ** will be in Shenzhen International Convention and Exhibition Center kicked off. As Asia's largest plastics and rubber industry exhibition, this exhibition to “intelligent - recycling - sustainable” as the theme, bringing together more than 3,000 global top enterprises and 100,000 + professional visitors.

HTsorter will bring the latest generation of AI intelligent plastic sorting solutions to make a grand appearance (Booth No.: 602, Hall 10), to show the revolutionary Plastic Sorting Machine and Polymer Sorter technology to the global customers, and to promote the transformation and upgrading of the plastics recycling industry to the high efficiency and precision.

Technology Highlights

1. AI Visual Recognition System: Redefining Sorting Precision

The Polymer sorter-X series polymer sorting machine on display is equipped with self-developed multi-spectral sensing + deep learning algorithms, which can accurately identify 20+ types of plastics, such as PP, PE, ABS, etc. Even in the face of complex mixed wastes, the sorting purity is still as high as 99.8%, which is much higher than the average level of the industry.

2. Industry 4.0 Intelligent Ecology

Real-time monitoring of sorting efficiency, energy consumption data and equipment health status.

Support cloud data interconnection, seamless connection to MES/ERP system.

Modularized design, suitable for film crushing line, bottle cleaning line and other scenarios.

3. Benchmark Of Circular Economy Practice

The annual processing capacity of a single machine exceeds 15,000 tons, helping customers reduce manual sorting costs by 30%, reduce raw material waste by 20%, and reduce carbon emissions by 5,000 tons per year, which accurately responds to the needs of the global “Waste Ban” and ESG strategy.