As industries worldwide prioritize sustainability and operational efficiency, intelligent color sorting technologies are undergoing transformative advancements. At HT Sorter, we're at the forefront of this evolution, delivering cutting-edge solutions that redefine how businesses manage material purity and recycling workflows.

Precision Through Advanced Plastic Optical Sorter Technology

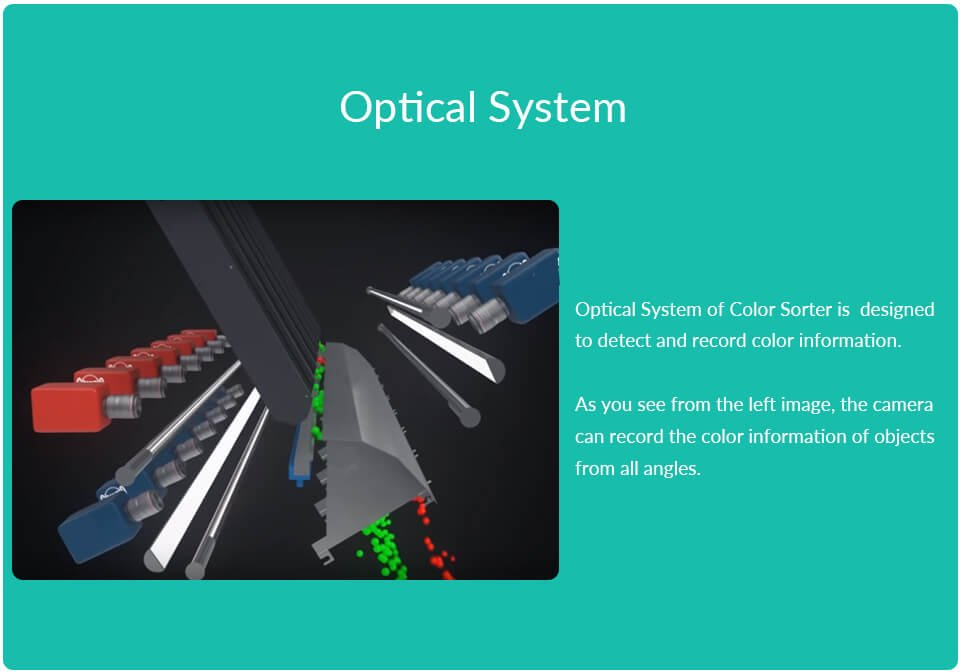

Modern recycling and manufacturing demand systems that go beyond basic color detection. Advanced plastic optical sorter technology now integrates hyperspectral imaging and near-infrared (NIR) spectroscopy to analyze materials at a molecular level. This enables precise identification of polymers like PET, HDPE, and PVC, even in mixed streams. For example, in plastic recycling, such technology ensures contaminants as small as microns are removed—critical for meeting food-grade safety standards. HT Sorter's systems leverage these innovations to achieve 99.9% sorting accuracy, transforming complex waste into high-value resources.

Speed Meets Sustainability with High-Efficiency Plastic Pellet Color Sorters

In high-volume production environments, speed and consistency are non-negotiable. High-efficiency plastic pellet color sorters combine rapid processing (up to 8 tons per hour) with energy-saving designs. These systems utilize adaptive air-jet ejection and real-time monitoring to maintain throughput without compromising precision. For industries like injection molding or packaging, this means reduced downtime and material waste. HT Sorter's modular designs allow seamless scalability, ensuring businesses of all sizes can optimize their operations while aligning with circular economy goals.

AI-Powered Plastic Optical Sorting Machines: The Next Frontier

Artificial intelligence is revolutionizing material handling. AI-powered plastic optical sorting machines employ machine vision and deep learning to continuously improve sorting logic. By analyzing vast datasets, these systems adapt to new materials, shapes, and contamination patterns in real time. For instance, AI algorithms can differentiate between subtle color variations in post-consumer plastics or detect defects in industrial pellets—tasks that challenge traditional systems. HT Sorter's IoT-enabled platforms further enhance this capability, offering predictive maintenance and remote adjustments to minimize operational disruptions.

HT Sorter: Pioneering Smarter, Greener Solutions

The future of color sorting lies in intelligent, interconnected systems that balance performance with sustainability. HT Sorter's innovations—from advanced optical sorters to AI-driven automation—empower industries to reduce waste, cut costs, and meet stringent regulatory requirements. By integrating eco-friendly materials and energy-efficient processes, we're helping businesses transition toward greener practices without sacrificing productivity.

As global demand for recycled plastics and high-purity materials grows, HT Sorter remains committed to pushing technological boundaries. Our solutions aren't just tools; they're partners in building a cleaner, more efficient industrial ecosystem.